Solutions. Simplified.

Lakeland Monroe Group is a world-class supplier of decorative, precision and functional plastics, primarily for the Automotive Industry. Our entire team is dedicated to solving your manufacturing challenges. With over 75 years of combined strength, diverse capabilities and forward-thinking solutions, we strive to exceed our customer’s expectations, every day.

Our Diverse Capabilities

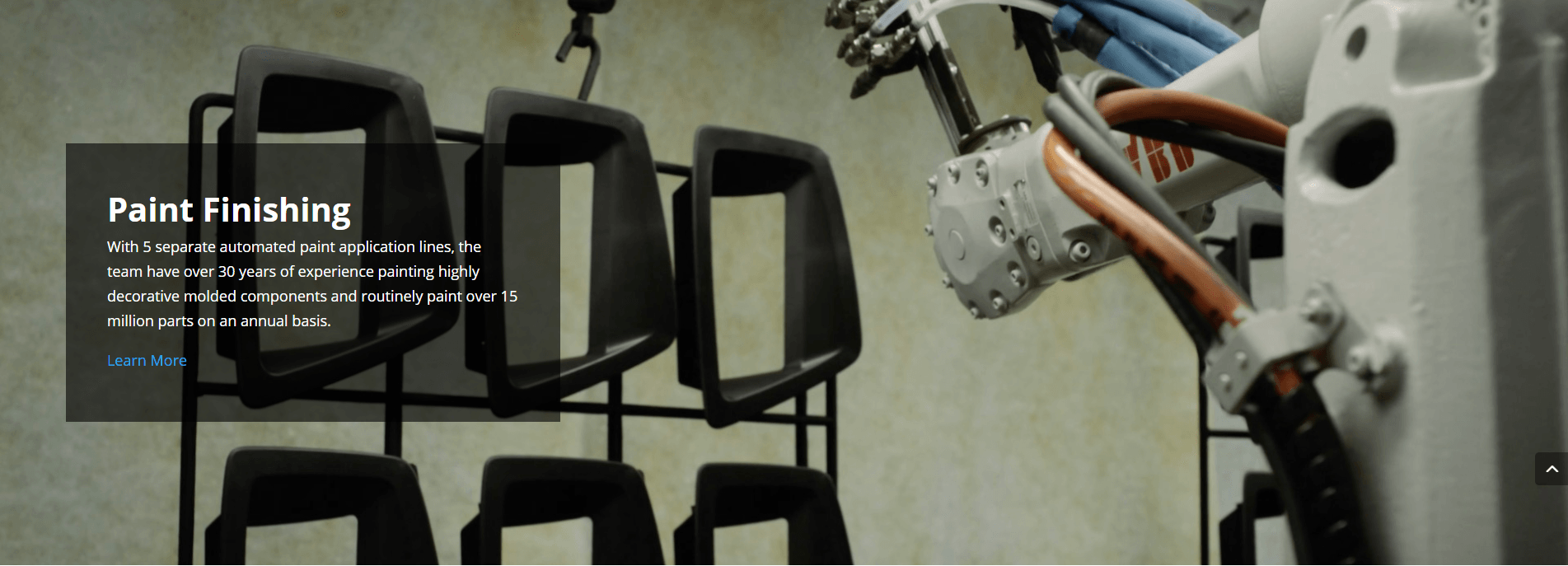

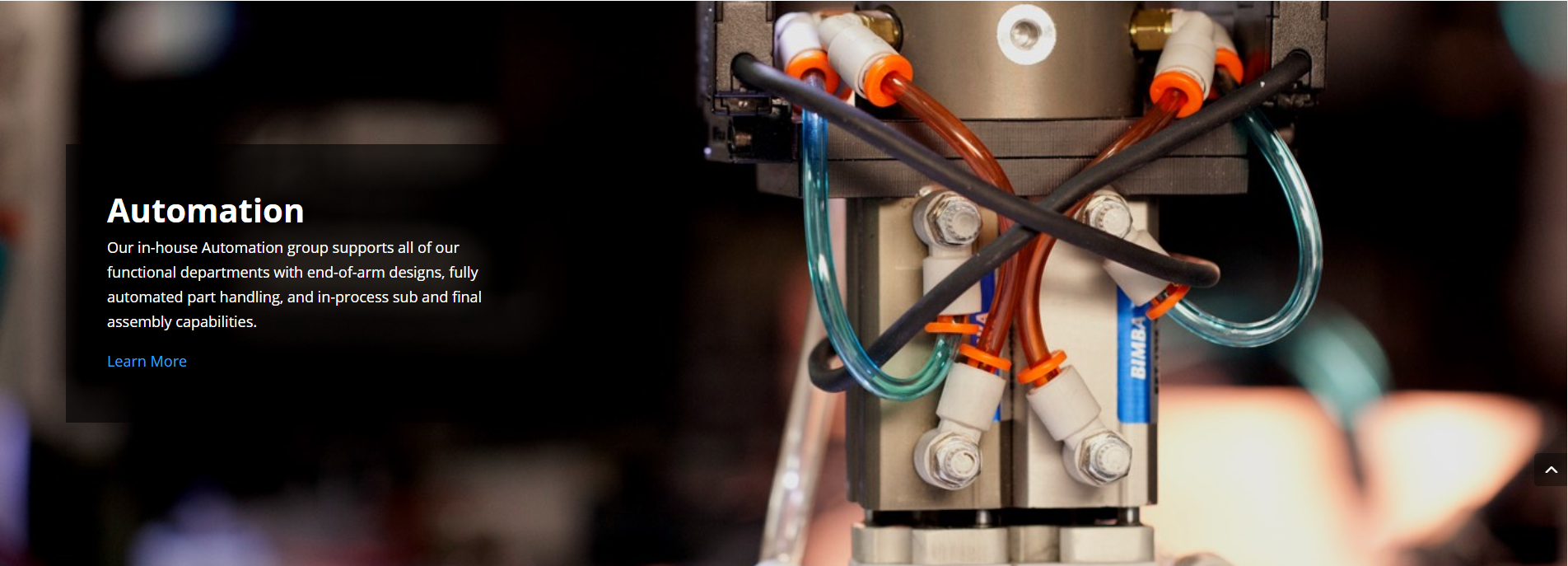

MANUFACTURING

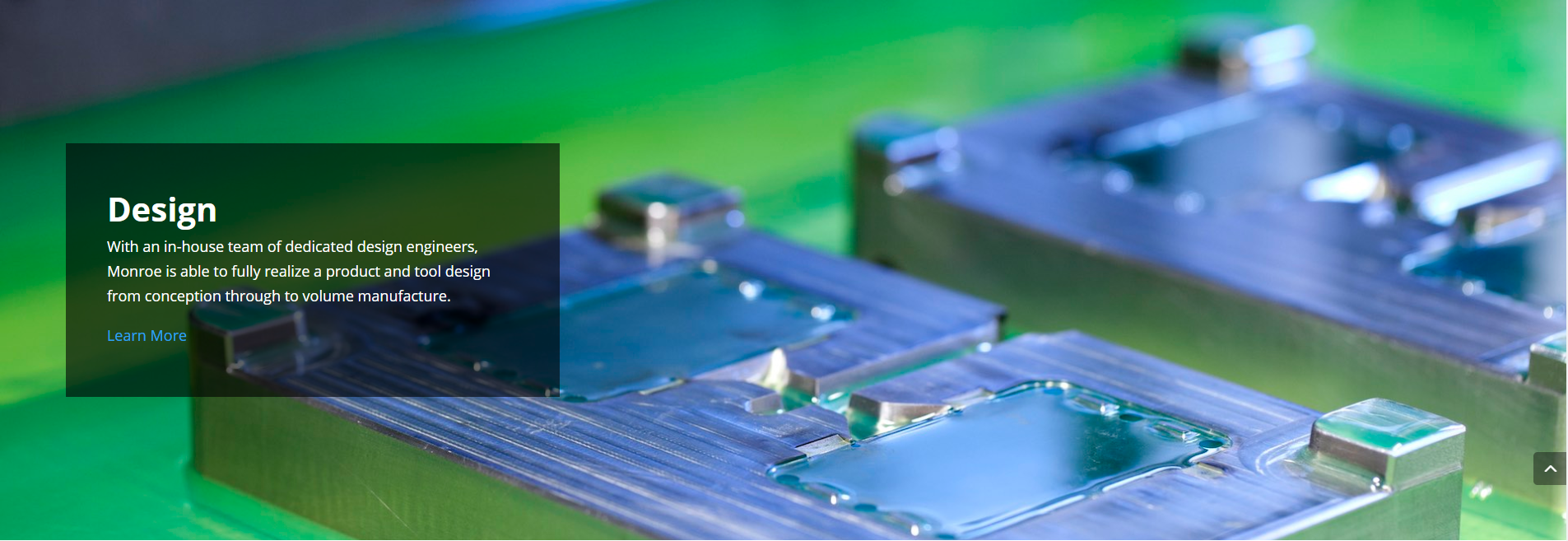

ENGINEERING